Obsolete hardware has been created by the Mr Windows team on a large scale 1000 + components, for a mining encampment in Jabiru for 50 year old windows, through to daily production of parts to meet individual orders.

3D Printer Hardware

Frustrated with the inability to find obsolete parts for customers, Mr Windows invested in 3D print technology in 2021 with the continued obsolescence of hardware and people needing to maintain and upgrade their hardware needs it filled the need to assist these customers.

Using our in-house team we can create the proto-type you need as a test piece or a final product. Get in contact with us and see how we can assist you.

Resources On Site

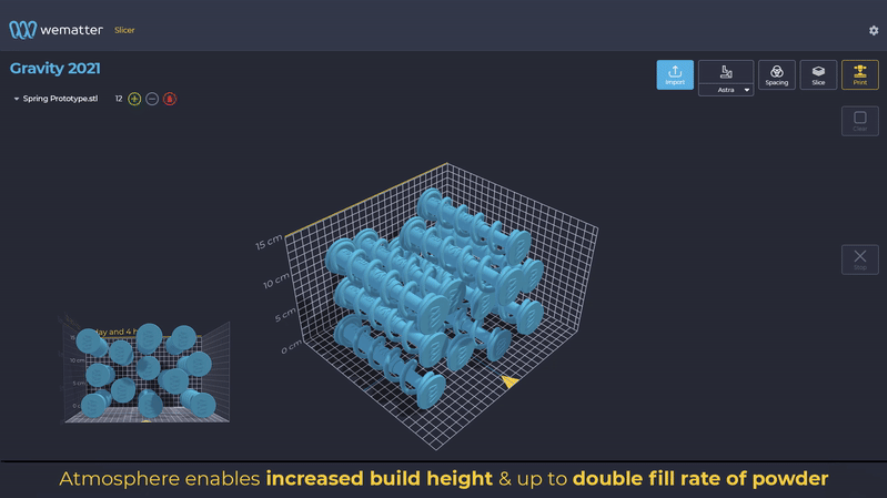

Mr Windows has 3 Industrial Grade 3D Printers using the latest software and technology to deliver solutions unavailable anywhere else.

So what is SLS - it stands for selective laser sintering (SLS) which is a 3d printing process (additive manufacturing) that uses high-powered lasers to sinter, or bind, finely powdered material together into a solid structure.

Our Markforged 2 enables our team inlay parts that have previously failed with carbon fibre, kevlar and fibre glass resulting in a product that boasts unmatched durability.

Introducing the Figure 4 Standalone, a state of the art industrial grade resin printer that prints the finer details perfectly.

We achieve fast turnarounds on functional prototyping and low volume production with ultra-high speeds. Our on-site Figure 4 Standalone offers quality, accuracy, industrial-grade durability, service, and support.

How Does It Work?

We have a 3 step process to take your part from prototype to working product.

-

Step 1.

Get in touch with our team to submit your part and provide information on your project.

-

Step 2.

Our team will design, reinforce, repair and produce your prototype and have it sent out within 8 weeks.

-

Step 3.

Trial the prototype and provide feedback to the team to take the product from a prototype to a working part.